The Drape Forming Method for Prosthetic Sockets

How to drape form with Orfitrans Excel

The drape forming method is a tried and tested method for the fabrication of (inner) prosthetic sockets and orthoses. In contrast to the bubble/blister forming method, drape forming involves using a flat, heated thermoplastic sheet and manually forming it around a model.

Thanks to its self-adhesive properties, Orfitrans Excel lends itself perfectly to this method. It is a lightweight material that pulls easily and uniformly for comfortable sockets and orthoses.

Read on to discover our best drape forming tips and tricks and learn how to get optimal fabrication results from Orfitrans Excel.

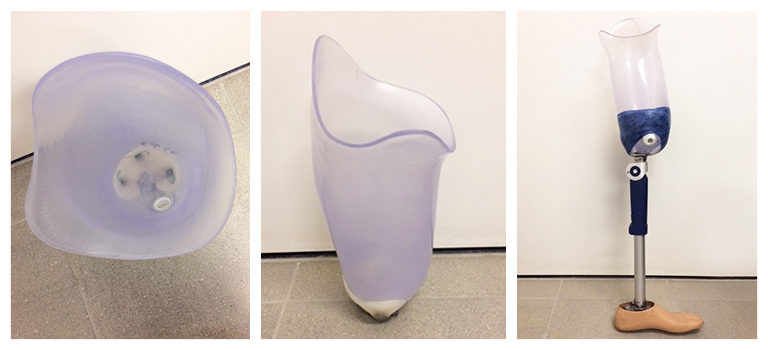

For this article, we’ll be focusing on the fabrication of a transtibial prosthetic socket.

When to use drape forming

Both drape and bubble forming work perfectly to create qualitative, durable O&P products. The choice between the two methods is entirely dependent on the personal preference of the prosthetist.

The drape forming method has a couple of specific benefits:

- Vacuum equipment is not required. However, we recommend that drape forming be combined with a vacuum to optimize the thermoforming.

- Drape forming makes it easier to maintain an even thickness across the entire socket or orthosis.

You could consider using drape forming in the following instances:

- When you are working with smaller models.

- When an even thickness is essential.

- When using thinner thermoplastic sheets.

- For orthotic applications.

Drape forming a transtibial prosthetic socket

Thermoplastic Materials

Orfitrans Excel is the material of choice for the drape forming method, because of its self-adhesive properties. These thermoplastic sheets are available in a wide range of thicknesses, but we do recommend choosing a thickness of 3, 4 or 5 mm.

For this article, we are using a 4 mm thick Orfitrans Excel sheet.

Step 1: Prepare the positive model

- Position and install a plaster, foam or wooden positive model.

- If using, connect a vacuum system. We’ll be showing the drape forming method without a vacuum.

- Treat the model with a very light layer of silicone spray and rub it in.

![]()

If you prefer, you can apply a cotton stockinette to facilitate socket removal. Do keep in mind that the pattern of the fabric can transfer onto the thermoplastic material.

Read our article about creating the perfect positive model for more tips and tricks.

Step 2: Heat the thermoplastic sheet

Orfitrans Excel 4 mm should be heated at a temperature of 130°C (266°F) for 6 minutes (convection) or 3.5 minutes (infrared). Have a look at the Orfitrans Activation Poster for an overview of activation temperatures/times for all Orfitrans materials.

- Heat the Orfitrans Excel sheet in a convection or infrared oven.

- Place the material flat on a Teflon sheet.

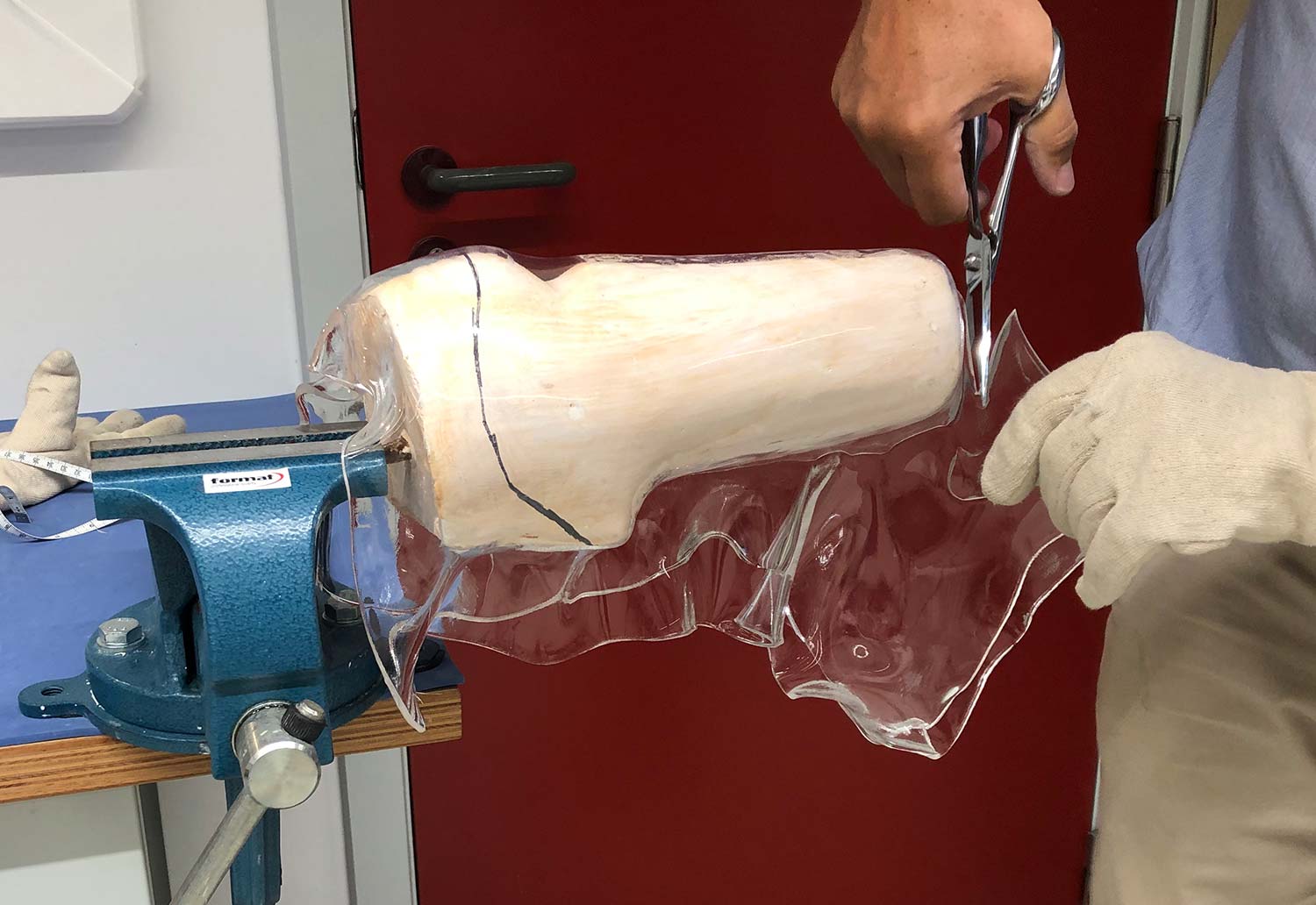

Step 3: Form the sheet on the positive model

- Position the positive model at a horizontal angle.

- Take the Orfitrans Excel sheet out of the oven and drape the material over the positive model.

- Create a seam along the underside of the model by pressing the material together.

- While the material is still hot, use scissors to cut away excess material and to create a seam.

- Wearing heat-resistant gloves, form and press the material around the model. Make sure it conforms well and try to avoid air bubbles.

.

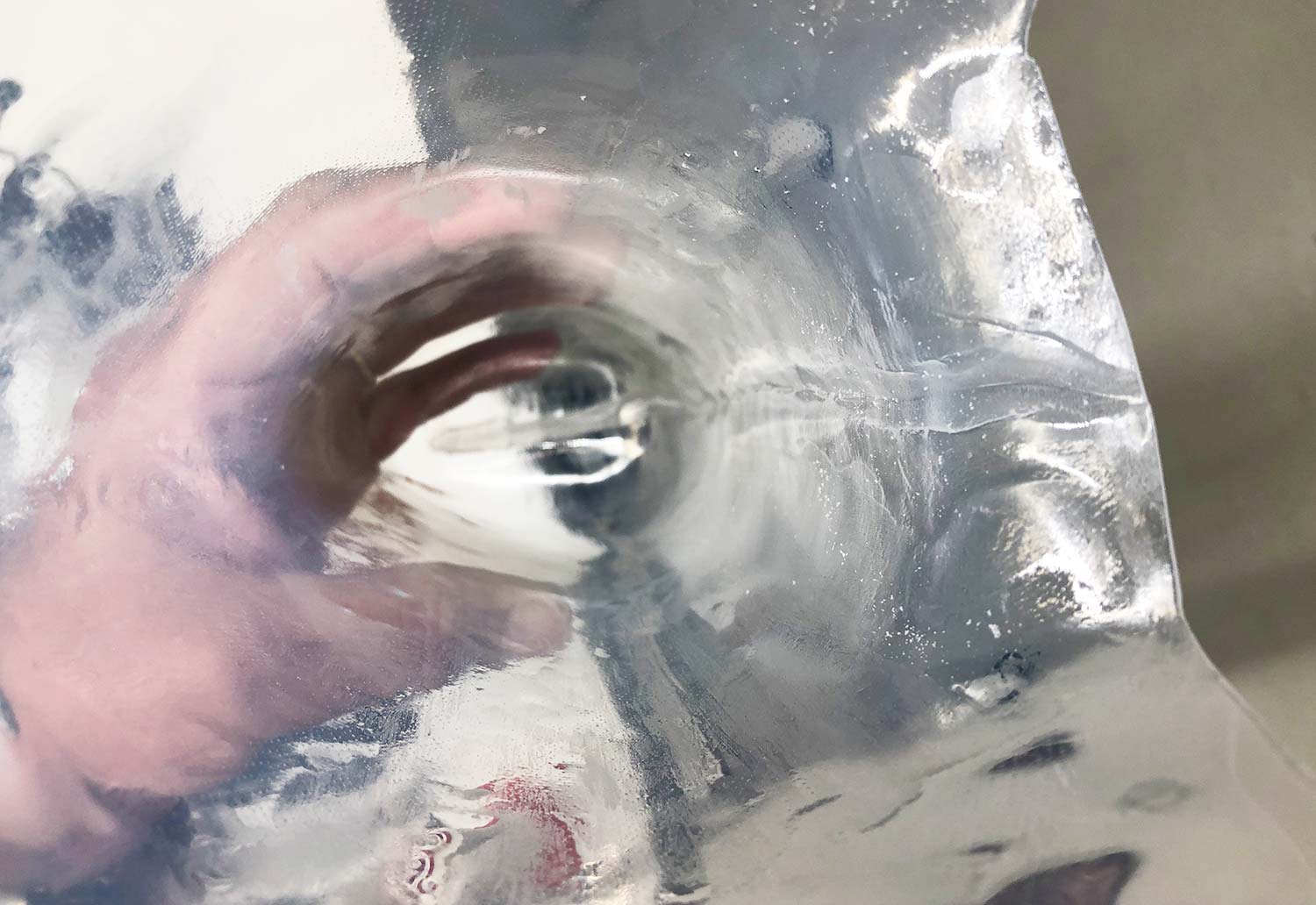

Step 4: Smooth out the seam

- Use pliers to secure the bond of the seam.

- Carefully trim any excess material with a cutter.

- Grind and polish the seam to make it flat and smooth.

- To make the seam extra flat, you can lightly reheat the area with a heat gun.

- Using a narrow round object, such as a screwdriver, roll along the seam to flatten and smooth it out. Take your time for this step; the seam should become almost undetectable.

.

Step 5: Finish the socket

Remove the socket from the model to trim and polish the edges. Read more about this final step.

![]()

Written by Marc Blij

Marc studied in Brussels and London and is a Certified Orthotist and Prosthetist.

After working in an O&P lab at the Universities of Louvain and Brussels, he decided to set up his own O&P lab in Antwerp. For over 30 years, he ran his own practice, together with his wife.

Since 2006, Marc works at the Orfit Industries headquarters in Wijnegem (Belgium) as a Product and Educational Specialist in Orthotics & Prosthetics and Physical Rehabilitation.

![]()

If you’d like to receive the latest product updates and interesting Orfit news, subscribe to our newsletter: