Advantages of Using a Thermoplastic Check Socket

Using a test socket to obtain the perfect fit

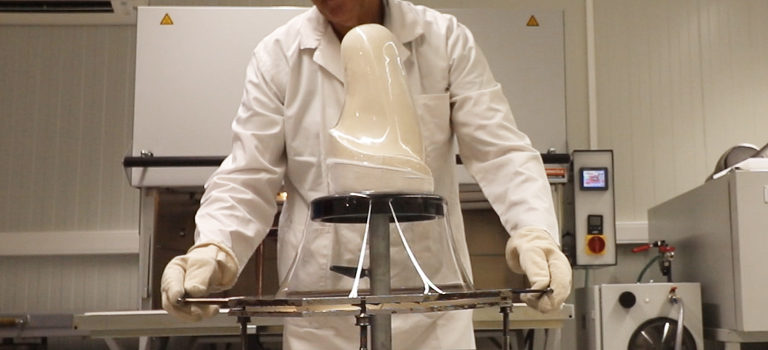

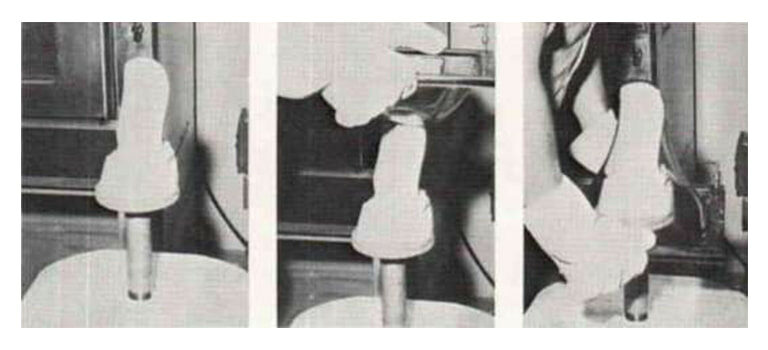

Since their first use in the mid-20th century, transparent check or test sockets have become an indispensable tool for the fabrication of stable, comfortable and functional prostheses.

A check socket is an essential aid in the creation of a qualitative definitive socket that will last the patient many years.

Taking the extra time to fit the patient with a check socket before fabricating the definitive socket pays off in the long term and offers both the patient and the prosthetist many advantages.

Importance of a well-fitting socket

It goes without saying that a prosthetic socket should fit the patient perfectly. The socket forms the base of the prosthesis and is the component that is in direct contact with the patient’s residual limb. It should offer the support and conformity needed for the patient to comfortably walk in their prosthesis.

It goes without saying that a prosthetic socket should fit the patient perfectly. The socket forms the base of the prosthesis and is the component that is in direct contact with the patient’s residual limb. It should offer the support and conformity needed for the patient to comfortably walk in their prosthesis.

An ill-fitting socket could result in various complications that may affect the mobility and overall well-being of the patient, such as:

- Bad or no control over the prosthesis

- Skin irritations

- Ulceration

- Pain

- Stress

How the check socket can help

An article by Aydin and Okur (2018) studied the effects of a check socket on patient satisfaction, pain and functionality in patients with lower limb amputation. The research was conducted in two groups:

- One group that used a check socket before their definitive socket.

- A second group that did not use a check socket and received their definitive socket immediately.

The patients with the check socket visited the clinic weekly and had adjustments made to their socket according to their wearing issues. After this evaluation period was done, they had their definitive socket made. The group without the check socket, on the other hand, did not have this evaluation period and received their definitive socket right away.

Overall, the patients who were fitted with a check socket were more satisfied with their prosthesis, experienced less pain and found their final prosthesis more comfortable and functional.

Advantages of a thermoplastic check socket

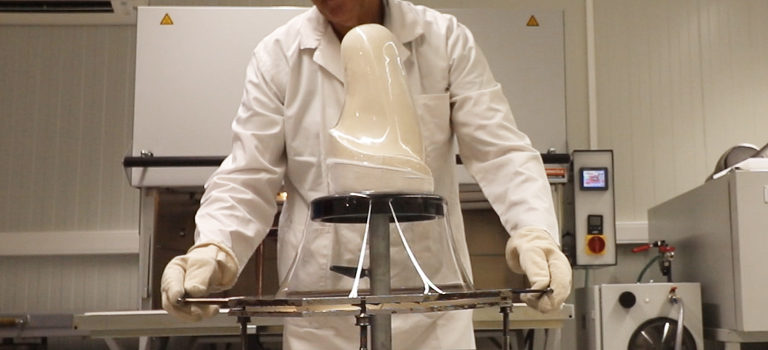

Today’s advanced thermoplastic materials have specific properties that maximize the benefits of a check socket:

Durability

Durable thermoplastic materials now allow for a longer evaluation period. The patient can take their socket home without the risk that the material will break, crack or shatter.

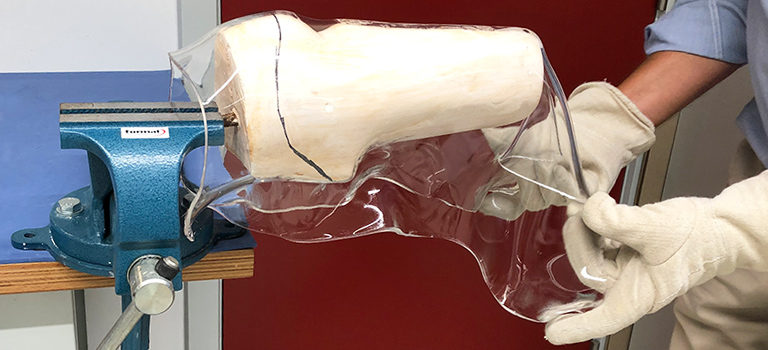

Transparency

Transparency

The transparency of check socket materials gives the prosthetist a good idea of

what is happening on the inside of the socket:

..– Pressure points

..– Hollow areas

..– Excess space between the inner and outer socket

Adjustability

It is possible to make small, local adjustments by re-heating the material with

a heat gun. It is also very easy to stick pads inside the socket to fill up open

spaces.

While the application of a check socket takes more time and patience, it results in a more comfortable and functional prosthesis that lasts the patient a long time.

Reference

Aydın, A., & Çağlar Okur, S. (2018). Effects of Test Socket on Pain, Prosthesis Satisfaction, and Functionality in Patients with Transfemoral and Transtibial Amputations. Medical Science Monitor, 24, 4031–4037. https://doi.org/10.12659/MSM.910858

![]()

Written by Marc Blij

Marc studied in Brussels and London and is a Certified Orthotist and Prosthetist.

After working in an O&P lab at the Universities of Louvain and Brussels, he decided to set up his own O&P lab in Antwerp. For over 30 years, he ran his own practice, together with his wife.

Since 2006, Marc works at the Orfit Industries headquarters in Wijnegem (Belgium) as a Product and Educational Specialist in Orthotics & Prosthetics and Physical Rehabilitation.

![]()

If you’d like to receive the latest product updates and interesting Orfit news, subscribe to our newsletter: