High-Temperature Orthoses: A Practical Guide

Drape forming long-term orthoses with Orfitrans Excel

High-temperature orthoses offer long-term and reliable support for patients with chronic or permanent conditions. Their sturdy and durable characteristics ensure optimal comfort and stability.

Drape forming is the fabrication method of choice when it comes to creating long-lasting orthoses from high-temperature thermoplastics.

In this guide, we give a basic overview of the steps for drape forming an orthosis using Orfitrans Excel. But first, let’s have a look at the differences between low-temperature and high-temperature thermoplastics.

.

Low-Temperature vs. High-Temperature Thermoplastics

Both low-temperature (LTTP) and high-temperature thermoplastics (HTTP) can be used for orthotic fabrication, so what are the differences between the two?

Temperature

Of course, the activation/heating temperature is the most significant distinguishing factor for the two types of materials. Our low-temperature thermoplastics (LTTP’s) (e.g. Orfit Classic, Aquafit NS, Orfilight) can be heated at 65°C (149°F) whereas high-temperature materials (HTTP’s) (Orfitrans) have an activation temperature of 130°C (266°F) – 160°C (320°F). The LTTP’s can be heated in a water bath (splint pan) or dry heater, while the HTTP’s require an infrared or convection oven.

Fabrication Process

Due to the high activation temperatures of HTTP’s, the orthotic fabrication process is very different from that of LTTP’s. Low-temperature thermoplastics can be moulded directly onto the patient. High-temperature thermoplastics, on the other hand, need to be formed on a model of the patient’s extremity. As a result, the forming of the model is an additional step in the fabrication process.

Orthotic Wear

High-temperature orthoses are well suited for prolonged or permanent wear, while lower-temperature thermoplastics are intended for immediate fitting and short-term treatment, especially for immediate use after trauma or surgery.

Drape Forming a High-Temperature Orthosis

1. The Mould

Position the mould of the patient’s extremity and make sure it is secure. It can be a plaster, foam or wooden model.

TIP: We advise using an additional vacuum when drape forming an orthosis, as it will guarantee a close fit. However, if the equipment is not available, the orthosis can also be drape formed without a vacuum.

Spray the mould very lightly with silicone spray and rub it into the surface.

.

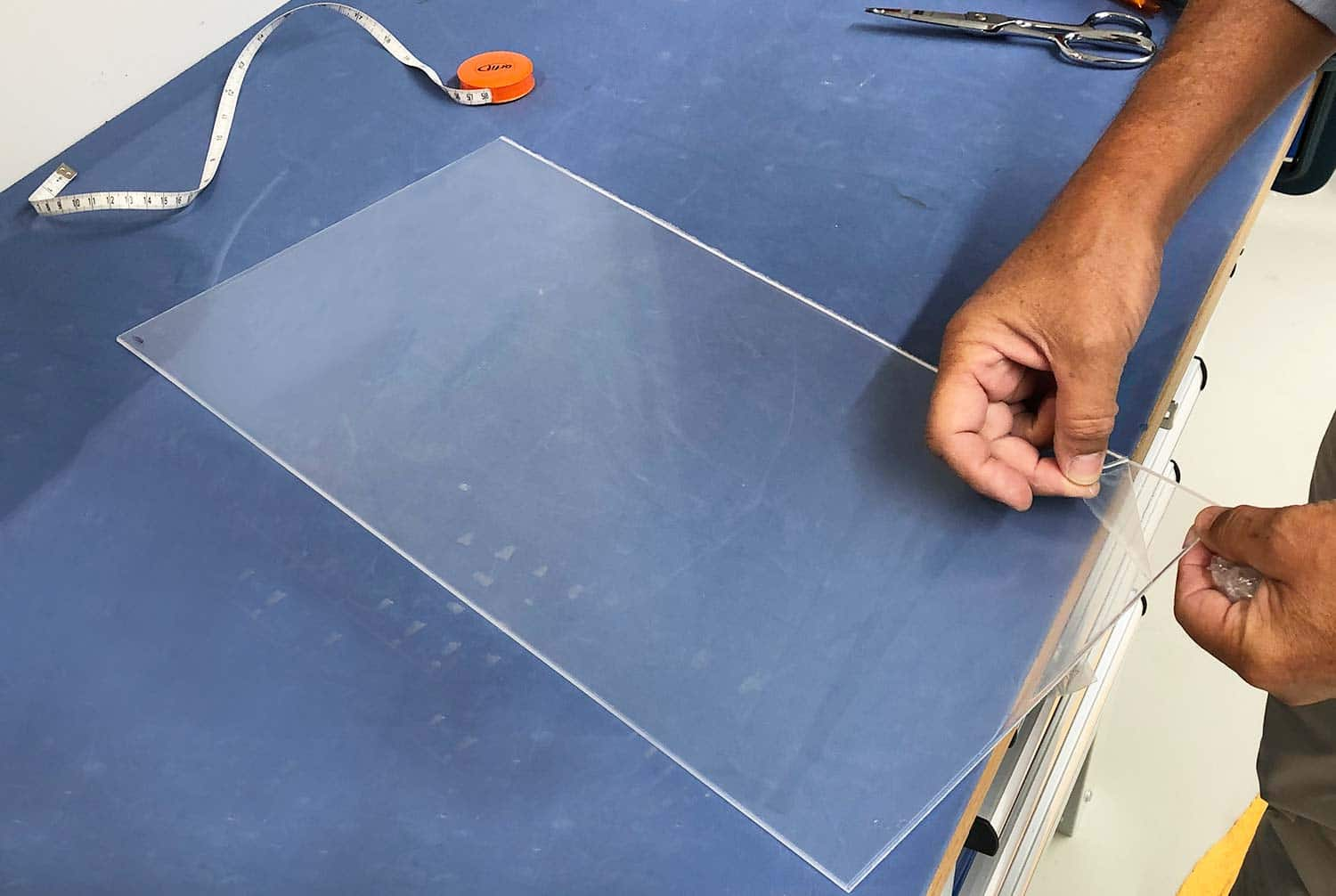

2. The Thermoplastic Sheet

For this orthosis, we are using an Orfitrans Excel sheet with 3 mm (1/8”) thickness. Orfitrans Excel is the lightest in weight of our high-temperature thermoplastic materials and has excellent drape forming characteristics.

Measure the model and cut the sheet in a suitable size. Remove the protective foil on both sides of the thermoplastic.

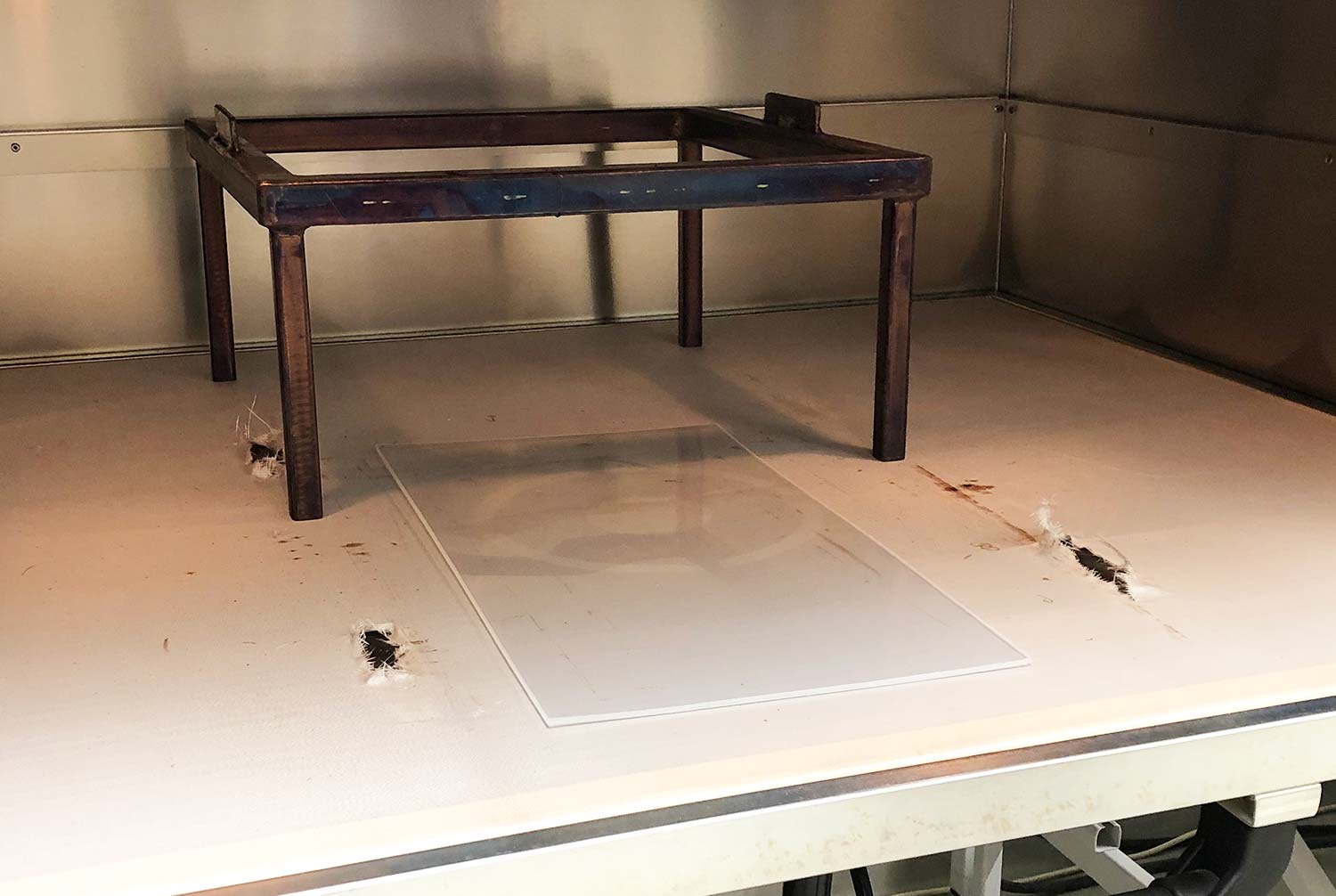

Heat the thermoplastic flat on a Teflon sheet in an infrared or convection oven.

TIP: Check the recommended activation temperatures for Orfitrans Excel to get optimal results.

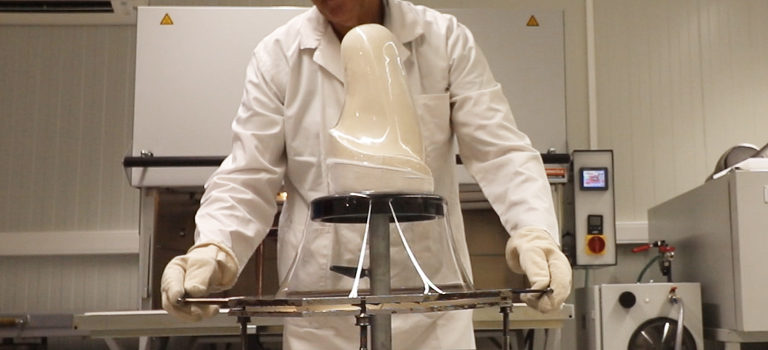

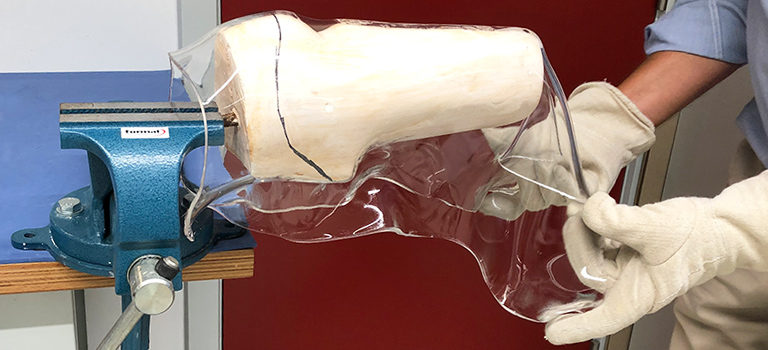

3. The Drape Forming

Form the sheet around the mould and create a seam. Work quickly, yet carefully to ensure an even thickness in all areas, avoid air bubbles and prevent any open spaces.

Once all edges are sealed, turn on the vacuum (if using). Then, cut the excess material while it is still hot.

.

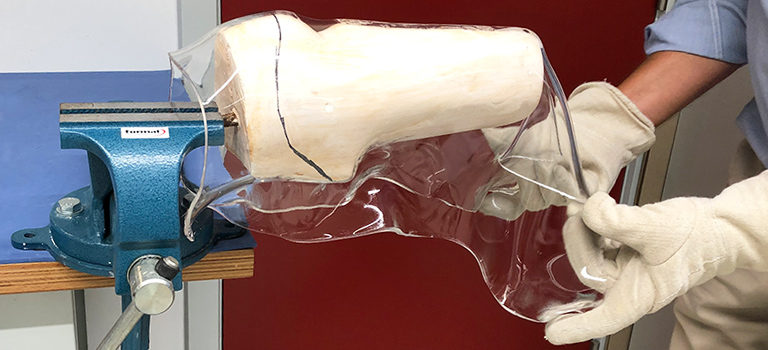

4. The Removal

Make a slit in the thermoplastic with a box cutter and carefully slip the orthosis off the mould.

Roughly trim the edges with scissors. These will be perfected in the next step.

.

5. The Finishing Process

Finish and smooth the edges of the orthosis. This step is very similar to the finishing process of a thermoplastic socket. If you want to learn more, read our blog post about the proper finishing technique for high-temperature thermoplastic products.

TIP: When polishing the edges, do not use a rotational speed higher than 1500 rpm, to prevent the thermoplastic from melting.

When the orthosis is finished, you can check the fit on the patient and attach a closure system. If necessary, adjust the shape by spot heating the thermoplastic with a heat gun.

![]()

Written by Marc Blij

Marc studied in Brussels and London and is a Certified Orthotist and Prosthetist.

After working in an O&P lab at the Universities of Louvain and Brussels, he decided to set up his own O&P lab in Antwerp. For over 30 years, he ran his own practice, together with his wife.

Since 2006, Marc works at the Orfit Industries headquarters in Wijnegem (Belgium) as a Product and Educational Specialist in Orthotics & Prosthetics and Physical Rehabilitation.

![]()

If you’d like to receive the latest product updates and interesting Orfit news, subscribe to our newsletter: